BOLLINGER B1 ELECTRIC SUV

ALL ELECTRIC. ALL WHEEL DRIVE. ALL TERRAIN.

Bollinger Motors was originally founded in the Catskill Mountains of New York in 2015. After 2 years of development, the small team revealed their first electric truck prototype in 2017. It was Robert Bollinger's dissatisfaction with his traditional work truck on his cattle farm that led him to pursue a solution that would blend his taste for rugged utility and minimalist, timeless design.

This is a highlight reel of the design theory and execution of his vision for the no-frills, robust and highly capable electric truck of his dreams.

DESIGN ETHOS

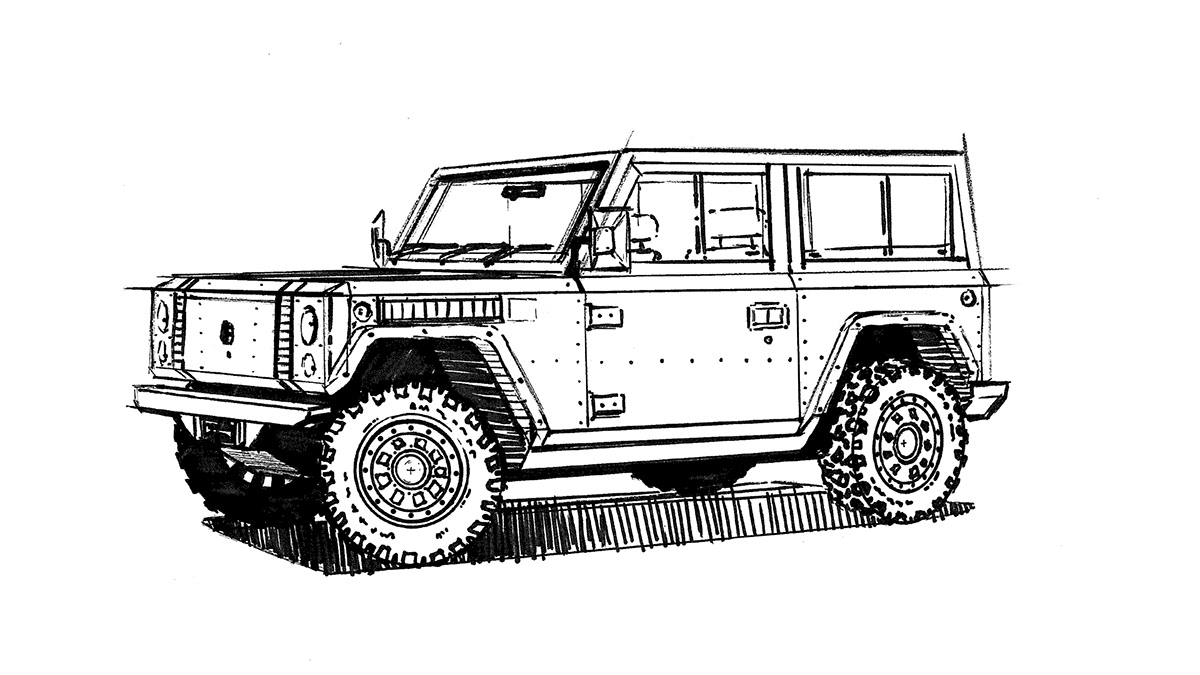

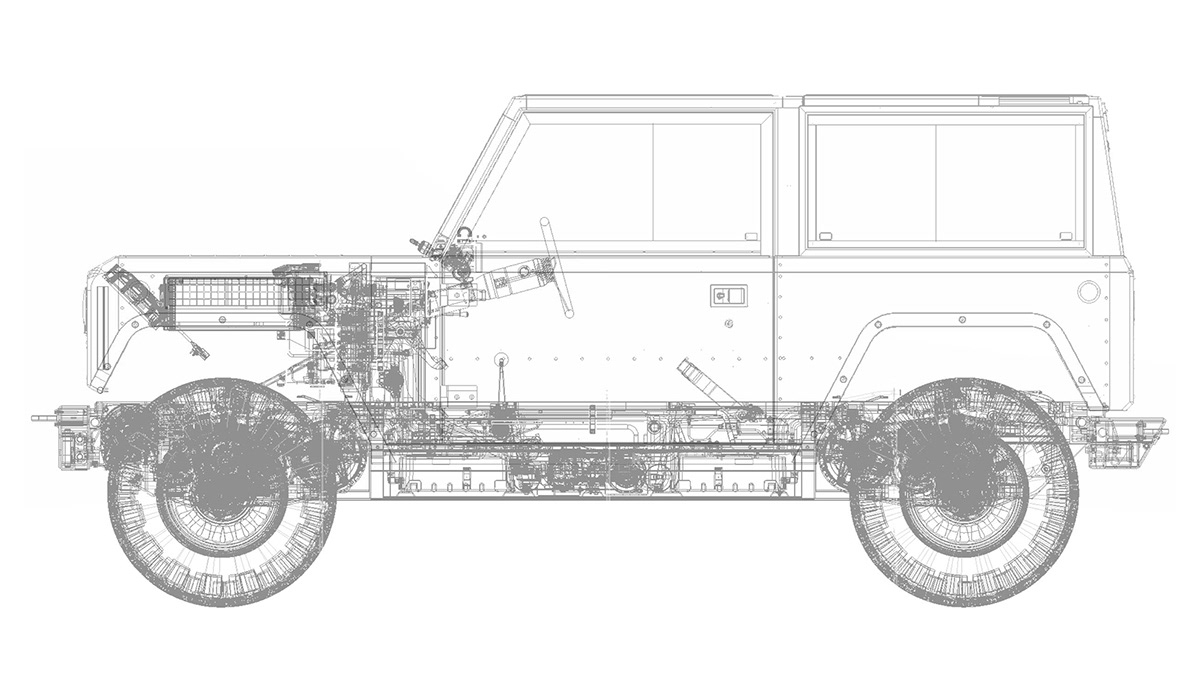

More architecture design than traditional automotive design, the B1 is entirely constructed with straight, parallel lines and broad surfaces punctuated with aircraft-style rivets. The straight line design language was not a pure aesthetic decision-- it was a direct result of the engineering and manufacturing process. The B1 was always meant to be a low-volume hand-built enterprise with minimal to no stamping of the body panels. Therefore, the fenders, doors, frunk-gate and tailgate were all hand made in a press brake. The panels were bonded and riveted to the underlying aluminum body structure.

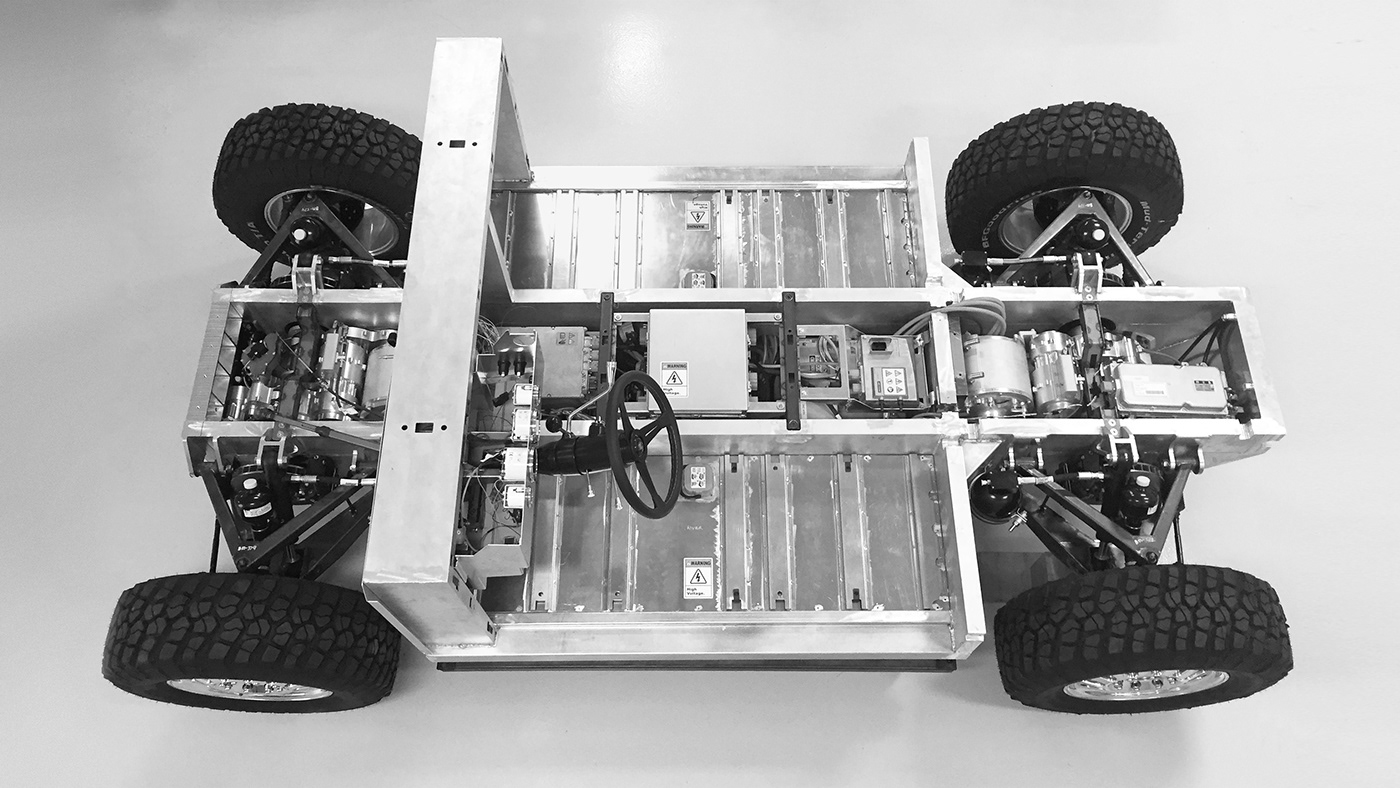

At the time, no electric trucks existed on the market so many components needed to be created from scratch, which led to new opportunities to design and engineer individual parts for better durability, modularity and simplicity.

TRUCK & SUV

With a from-scratch design, came the opportunity to redesign the functionality with a new vehicle packaging layout. The cab can convert from a traditional SUV to a pickup bed by removing the horizontal upper supports and moving the back hatch glass forward to attach at the B-pillar.

The Bollinger Motors Patented Passthrough

Robert always knew that the future would be electric, but he didn't set out to make an electric truck just to save the planet, he saw the benefits of electrification for a work truck. Instant torque at zero RPM means more pulling power on the farm. 120V and 240V export power means your truck is now your mobile generator for table saws, welders, tools etc. No big V8 taking up the entirety of the front of the truck means you can start from scratch and reimagine the internal storage spaces.

Spanning the entire length of the center of the vehicle--from front bumper to rear bumper-- the Pass Through allows long cargo to be stored inside the vehicle, out of the elements, but more importantly, not hanging past the tailgate or being shoved through the back window of the cab. It also allows for driver access to lockable, secure storage when the doors and top are removed from the vehicle.

Everything you need, and nothing you don't

The interior is spartan, yet the attention to detail feels welcoming as it begs you to spend a few moments exploring the details of the crisp edges, parallel gaps and nested corner radii of the all-aluminum dashboard. Keeping in mind it's farm-truck origins, the truck needed to be bare-bones-- eschewing the tradition of headliner padding, sound deadening pads, carpeting and plastic closeout coverings.

There is clarity in "honest materials". For example, if something is wood, let it be wood-- celebrate it by using stains that enhance the natural character of the wood texture. If something is plastic, don't stamp a wood grain in the surface, as if it were something it's not. Metal surfaces on the interior of trucks is nothing new, but in an effort to keep things "honest", the surface transition angles are all 90° which mates nicely to the parallel edges and clean corners from press-brake metal sheets.

FUNCTIONAL SIMPLICITY

Functionality in the B1 go hand-in-hand with it's overall aesthetic. Designing with this mindset, the resulting vehicle is both usable and inherently approachable. For instance, all of the exposed interior bolts and screws indicate to the user that a particular component can be removed, repaired, or modified. This may seem obvious, but hiding mounting hardware is the modus operandi of the car design industry today.

The truck was always meant to be an heirloom vehicle-- something to be used, repaired, modified and upgraded, with the end goal of handing the vehicle down to the next generation. It's a blank canvas ready for the day to day demands of hardworking people who appreciate a good tool and the stories that can be crafted from those tools.

THE B1 BALANCE

The difficulty in such reductionist design thinking is knowing when to say "enough" and deciding what amenities are just distractions. Conversely, there is a risk of going too minimal just for the sake of minimalism, at the expense of the end user experience. The B1 strikes a balance between minimal and functional that results in a blank canvas multi-tool. It's all about the experience behind the wheel, silently rolling through the woods, with no touch screen interfaces to distract from the world happening around us. The Bollinger B1 is -- first and foremost -- a tool.

THANK YOU FOR PERUSING

Not shown here are the countless hours of engineering, testing, and validation processes-- or the ups and downs of starting a car company from scratch. For that story, see the journey here.

Photography

Design

Bollinger Motors